In various industries, ensuring the safety and reliability of equipment and components under high-pressure conditions is paramount. High Pressure Test Units (HPTUs) play a critical role in validating the integrity and performance of such assets. This article aims to provide a comprehensive understanding of HPTUs, their applications, components, and the essential role they play in maximizing safety and efficiency across diverse industrial sectors.

What Are High Pressure Test Units?

High Pressure Test Units, also known as hydrostatic test units, are specialized systems designed to apply pressure to test the strength and integrity of pipelines, vessels, valves, and other components. These units conduct hydrostatic tests, which involve pressurizing the equipment or system with a liquid, typically water, to verify its ability to withstand the designated pressure without leaking or failing.

HPTUs find applications across a wide range of industries, including:

Oil and Gas: Testing pipelines and piping systems to ensure they can handle operational pressures and avoid leaks.

Petrochemical: Verifying the integrity of pressure vessels, tanks, and cylinders to prevent hazardous failures.

Aerospace: Ensuring the reliability of valves, fittings, and flanges used in high-pressure environments.

Manufacturing: Quality assurance and testing of hydraulic components and systems to maintain safety standards.

Construction: Checking the pressure ratings of various industrial equipment to ensure compliance with safety regulations.

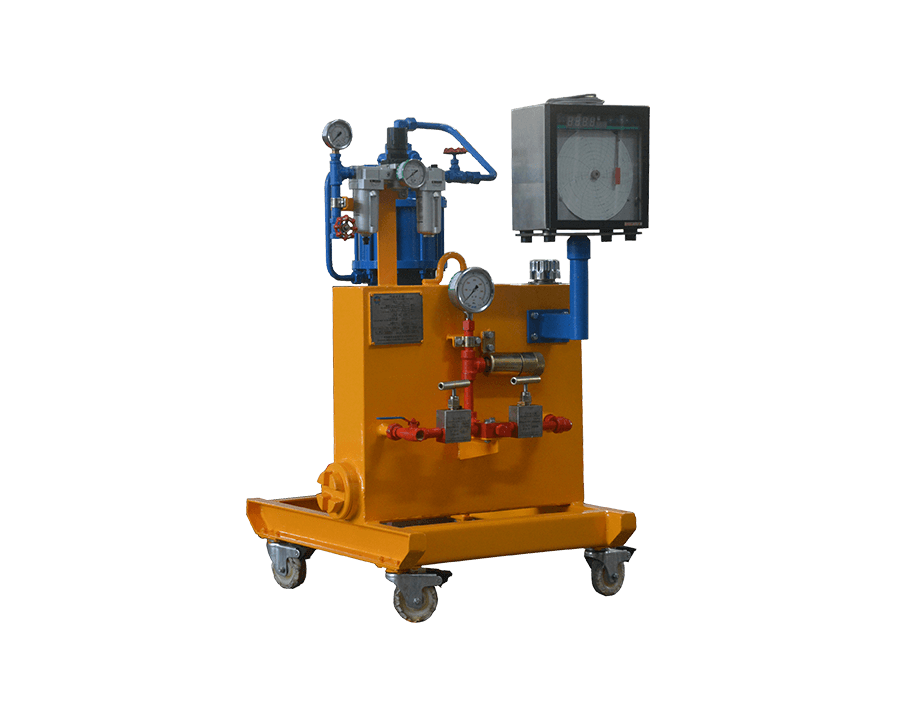

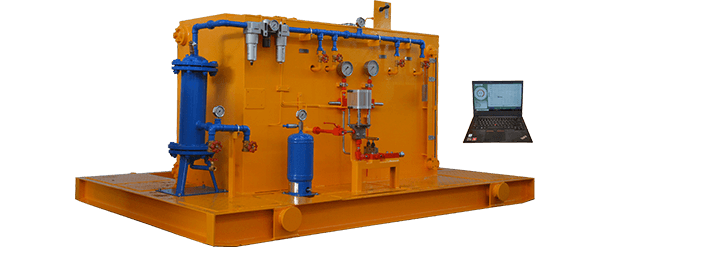

High Pressure Test Units consist of several key components that work together to create and maintain the required pressure for testing:

Pumping System: The pumping system generates the high pressure needed for the test. It typically includes a high-pressure pump, motor or engine, and associated control valves and instrumentation.

Pressure Control System: This system comprises pressure gauges, regulators, relief valves, and other devices that monitor and control the pressure applied during the test. These components ensure that the pressure remains within the specified range and provide safety measures in case of overpressure situations.

Fluid Handling System: The fluid handling system includes hoses, fittings, and connectors that deliver the pressurized fluid to the test object. It is essential to ensure that these components are rated for the intended pressure and are compatible with the test medium (usually water or hydraulic fluid).

Instrumentation and Data Recording: Modern HPTUs may feature advanced instrumentation for data recording and monitoring, allowing operators to track pressure, flow rates, and other parameters during the test. This data is crucial for compliance, quality control, and analysis of test results.

Ensuring Safety and Reliability

The use of High Pressure Test Units is fundamental to ensuring the safety and reliability of critical infrastructure and equipment. By subjecting components to rigorous testing, potential weaknesses or defects can be identified before they pose a risk in operational environments. This proactive approach to safety helps prevent catastrophic failures and environmental hazards and ensures compliance with industry standards and regulations.

Enhancing Efficiency

Efficiency is another key aspect of HPTUs. These units allow for rapid and accurate testing, enabling manufacturers, operators, and maintenance personnel to verify the integrity of equipment efficiently. By identifying potential issues early in the production or maintenance cycle, HPTUs contribute to minimizing downtime, reducing the likelihood of in-service failures, and optimizing asset performance.

Adherence to Safety Protocols

The use of HPTUs involves inherent risks associated with high-pressure operations. Therefore, strict adherence to safety protocols, guidelines, and regulations is essential. Operators and technicians involved in high-pressure testing must receive comprehensive training on safe operating procedures, equipment handling, and emergency response protocols. Regular inspection, maintenance, and certification of HPTUs are also crucial to ensure their continued safe and reliable operation.

High Pressure Test Units play a vital role in ensuring the safety, reliability, and performance of critical industrial equipment and infrastructure. By subjecting components to rigorous hydrostatic testing, HPTUs help identify potential weaknesses and ensure compliance with industry standards. The efficient and safe operation of HPTUs is essential for minimizing risks, optimizing asset performance, and maintaining the integrity of high-pressure systems across diverse industrial sectors. As technology and industry standards continue to evolve, the role of HPTUs in maximizing safety and efficiency remains indispensable.

By continuing to use the site you agree to our privacy policy Terms and Conditions.