In the oil and gas industry, managing high-pressure wells and preventing uncontrolled releases are critical for safety and operational efficiency. One of the essential components in this regard is the Blowout Preventer (BOP) stack. This sophisticated piece of equipment plays a crucial role in well control during drilling operations. This article explores the concept of a BOP stack, its components, functions, and significance in maintaining safety in oil and gas drilling operations.

A Blowout Preventer (BOP) is a large valve or series of valves installed at the top of a well to control and contain the pressure during drilling operations. It is designed to prevent blowouts, which are uncontrolled releases of crude oil or natural gas from a well. Blowouts can lead to catastrophic accidents, including explosions, fires, and environmental damage. The BOP stack is a critical safety device used to mitigate these risks.

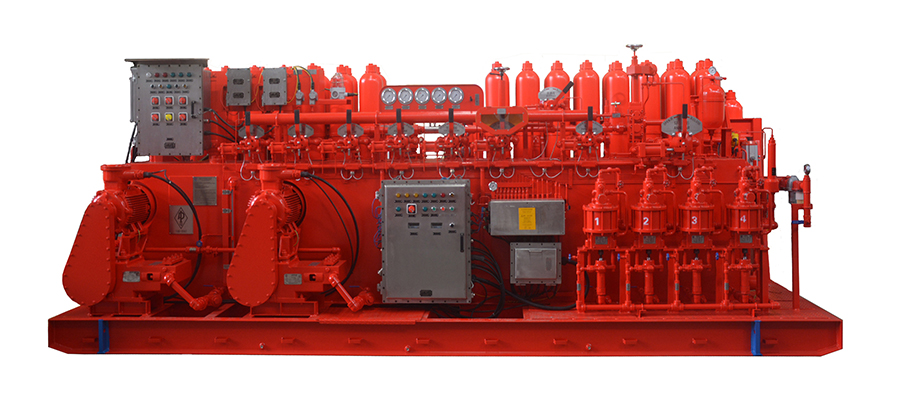

The BOP stack, also known as a BOP stack or stack assembly, refers to a configuration of multiple BOPs stacked vertically on top of one another, installed on the wellhead. This stack is used to manage and control the pressures encountered during drilling and to prevent the uncontrolled release of hydrocarbons. The stack includes various types of BOPs, each serving specific functions to ensure comprehensive well control.

A typical BOP stack consists of several key components, each designed to handle different aspects of well control:

Annular BOP

The annular BOP is a type of BOP that forms a seal around the drill pipe or other equipment in the wellbore. It is a large rubber or elastomeric seal that can expand and contract to close off the wellbore or seal around the pipe. The annular BOP is versatile and can be used to control various types of wellbore conditions, including gas kicks and partial obstructions.

Function: The annular BOP provides a reliable seal to control the wellbore and prevent fluid and gas escape. It is typically used in conjunction with other BOPs to provide an additional layer of safety.

Ram BOPs

Ram BOPs are mechanical devices with two or more "rams" that move toward each other to close off the wellbore. There are different types of ram BOPs, including:

Pipe Rams: Designed to seal around the drill pipe, these rams provide a tight seal and can contain high-pressure fluids and gases.

Blind Rams: These rams are used to completely seal off the wellbore when no pipe is present. They are essential for controlling well pressure when drilling operations are paused or completed.

Shear Rams: These rams are capable of cutting through the drill pipe and sealing the wellbore simultaneously. They are used in emergency situations where a blowout needs to be contained quickly.

Function: Ram BOPs are used to shut in the wellbore and prevent the flow of fluids and gases. They are essential for controlling high-pressure conditions and managing well control during drilling operations.

Choke and Kill Lines

Choke and kill lines are integrated into the BOP stack to allow for the controlled circulation of drilling fluids and to manage well pressures. These lines are connected to valves that regulate the flow of fluids and gases into and out of the wellbore.

Function: Choke and kill lines are used to manage well pressure, prevent blowouts, and control the flow of fluids during drilling. They are essential for maintaining well control and ensuring safe drilling operations.

Accumulator Unit

The accumulator unit is a hydraulic system that stores and supplies the hydraulic fluid needed to operate the BOP stack. It includes hydraulic pumps, accumulators, and control valves.

Function: The accumulator unit ensures that the BOP stack has a reliable source of hydraulic power to operate the BOPs effectively. It provides the necessary pressure to activate the BOPs and manage well control.

Control System

The control system is responsible for operating and monitoring the BOP stack. It includes control panels, sensors, and communication systems that allow operators to manage the BOPs remotely.

Function: The control system enables operators to activate and deactivate the BOPs, monitor well conditions, and respond to emergencies. It is essential for maintaining well control and ensuring the safety of drilling operations.

Functions of a BOP Stack

The BOP stack performs several critical functions in well control:

1. Preventing Blowouts

The primary function of the BOP stack is to prevent blowouts, which are uncontrolled releases of oil, gas, or drilling fluids from the wellbore. By sealing the wellbore and controlling well pressure, the BOP stack helps to manage and contain high-pressure conditions that could lead to blowouts.

2. Controlling Well Pressure

The BOP stack controls well pressure by regulating the flow of fluids and gases into and out of the wellbore. By managing well pressure, the BOP stack helps to prevent overpressure and maintain safe drilling conditions.

3. Sealing the Wellbore

The BOP stack provides a reliable seal around the wellbore to prevent the escape of fluids and gases. This seal is essential for maintaining well control and ensuring the safety of drilling operations.

4. Providing Emergency Response

In the event of an emergency, such as a blowout or equipment failure, the BOP stack provides a rapid response mechanism to contain the well and prevent further incidents. The shear rams and other components are designed to quickly shut in the well and manage high-pressure conditions.

The BOP stack is a crucial component in maintaining safety and operational efficiency during drilling operations. Its importance can be summarized as follows:

1. Safety Assurance

The BOP stack plays a vital role in ensuring the safety of personnel, equipment, and the environment. By preventing blowouts and controlling well pressure, the BOP stack helps to mitigate the risks associated with high-pressure drilling.

2. Environmental Protection

Blowouts can result in significant environmental damage, including oil spills and contamination. The BOP stack helps to prevent such incidents by providing a reliable means of controlling the well and containing any potential releases.

3. Operational Efficiency

Effective well control is essential for maintaining operational efficiency and minimizing downtime. The BOP stack enables operators to manage well pressure, seal the wellbore, and respond to emergencies, ensuring smooth and efficient drilling operations.

4. Regulatory Compliance

Regulatory agencies and industry standards require the use of BOP stacks to ensure safe drilling practices. Compliance with these regulations is essential for maintaining safety and meeting industry standards.

While the BOP stack is a critical safety device, it also presents some challenges and considerations:

1. Maintenance and Inspection

Regular maintenance and inspection of the BOP stack are essential to ensure its proper functioning. This includes checking hydraulic systems, seals, and control systems to identify and address any potential issues.

2. Complexity and Cost

The BOP stack is a complex assembly of various components, which can be costly to install, maintain, and operate. Proper planning and budgeting are required to manage these costs effectively.

3. Training and Expertise

Operating and maintaining the BOP stack requires specialized training and expertise. Personnel must be knowledgeable about the system's components and functions to ensure safe and effective operation.

The BOP stack is a vital component in managing high-pressure wells and preventing blowouts during drilling operations. Its sophisticated design, consisting of various BOPs, choke and kill lines, and control systems, plays a critical role in ensuring safety, operational efficiency, and environmental protection. While the BOP stack presents some challenges, including maintenance, cost, and training, its importance in well control cannot be overstated. As the oil and gas industry continues to evolve, the BOP stack remains a cornerstone of safe and effective drilling practices.

By continuing to use the site you agree to our privacy policy Terms and Conditions.