In the oil and gas industry, precise control of processes is essential to ensure safe, efficient, and reliable operations. Pneumatic controllers play a critical role in this domain, offering a robust and versatile solution for controlling various process parameters such as pressure, temperature, and flow. This article delves into the details of what a pneumatic controller is, how it functions, its applications in the oil and gas sector, and the benefits it provides.

Pneumatic controllers are devices that use compressed air as a power source to control the process variables. These controllers are commonly used in industrial automation systems where electronic or electric power might be impractical or undesirable. The basic principle of operation involves converting a physical input, such as pressure or temperature, into a pneumatic output that adjusts valves, actuators, or other control devices.

In oil and gas, pneumatic controllers are often preferred due to their reliability in harsh environments, such as offshore platforms and remote drilling sites, where electrical systems may be prone to failure or require extensive maintenance.

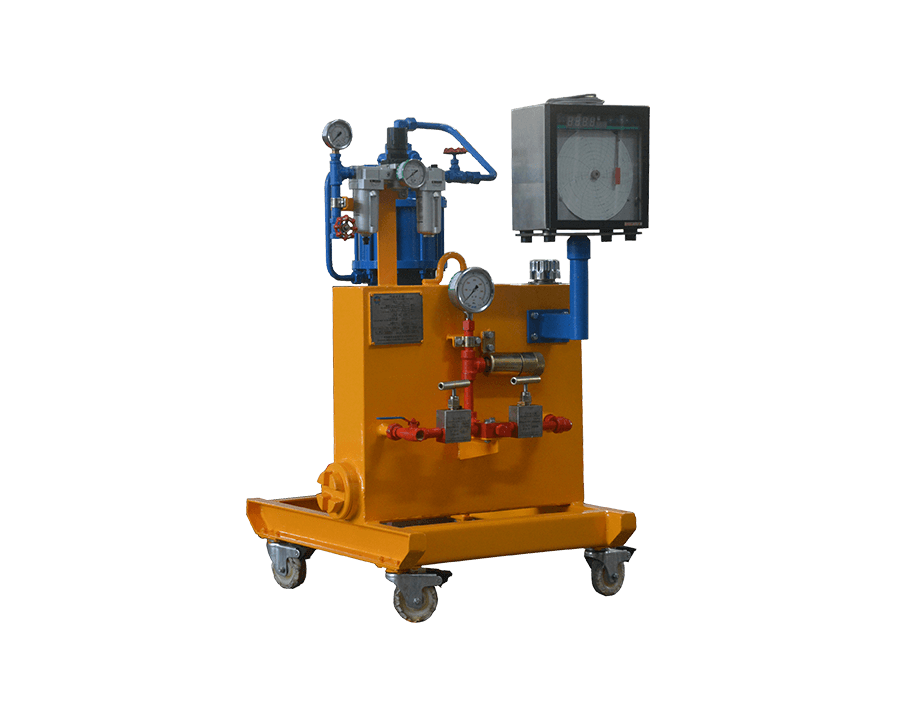

A typical pneumatic controller consists of several key components that work together to regulate process conditions:

Sensing Element: This component detects the process variable (e.g., pressure or temperature) and sends a corresponding signal to the controller.

Transducer: The transducer converts the detected signal into a pneumatic signal.

Controller Mechanism: The controller mechanism processes the signal and determines the necessary action to maintain the desired setpoint.

Output Device: The output device, usually a valve or actuator, adjusts the process condition based on the controller's instructions.

These components work in unison to ensure that the process remains within the desired operating parameters, even under varying conditions.

Pneumatic controllers can be categorized into different types based on their functionality and application. Some common types used in the oil and gas industry include:

Pressure Controllers: These controllers regulate pressure within a system by adjusting the flow of gas or liquid through a valve. They are essential in maintaining stable pressure in pipelines, compressors, and storage tanks.

Temperature Controllers: Temperature controllers maintain the desired temperature in process vessels, heat exchangers, and other equipment. By adjusting the flow of heating or cooling fluids, they ensure optimal operating conditions.

Flow Controllers: Flow controllers manage the flow rate of fluids within pipelines and processing equipment. They are crucial in ensuring the correct distribution of resources throughout the system.

Level Controllers: These controllers maintain the fluid level in tanks, separators, and other storage facilities. They prevent overfilling or depletion of resources, ensuring continuous operation.

Each type of controller is tailored to specific process needs, and their selection depends on the operational requirements of the oil and gas facility.

Pneumatic controllers are widely used in various oil and gas applications due to their robustness and reliability. Some common applications include:

Wellhead Control: Pneumatic controllers are used to regulate the pressure and flow of fluids at the wellhead. They ensure safe and efficient extraction of oil and gas while preventing blowouts and other hazardous situations.

Pipeline Management: In pipelines, pneumatic controllers help maintain the desired pressure and flow rates, ensuring the safe transportation of oil and gas over long distances. They also play a role in leak detection and isolation.

Compressor Stations: Pneumatic controllers regulate the pressure and temperature in compressor stations, which are essential for boosting the pressure of gas in pipelines. They help maintain optimal operating conditions and prevent equipment damage.

Refinery Operations: In refineries, pneumatic controllers are used in various processes, such as distillation, cracking, and treatment. They ensure precise control of temperature, pressure, and flow, leading to efficient refining operations.

Offshore Platforms: Offshore platforms rely heavily on pneumatic controllers due to their ability to operate in harsh marine environments. These controllers regulate processes such as drilling, production, and safety systems.

Pneumatic controllers offer several advantages that make them suitable for use in the oil and gas industry:

Reliability: Pneumatic controllers are known for their durability and ability to function in harsh environments, such as extreme temperatures, high pressures, and corrosive conditions. This reliability ensures continuous operation and reduces downtime.

Safety: Since pneumatic controllers do not rely on electricity, they are inherently safe for use in hazardous environments where electrical sparks could cause explosions. This makes them ideal for oil and gas facilities.

Simplicity: Pneumatic controllers are relatively simple devices with fewer components than electronic systems. This simplicity reduces maintenance requirements and increases the lifespan of the equipment.

Cost-Effectiveness: Due to their lower maintenance needs and long operational life, pneumatic controllers are a cost-effective solution for controlling processes in the oil and gas industry.

Scalability: Pneumatic controllers can be easily integrated into existing systems and scaled up or down based on the needs of the operation. This flexibility allows for efficient process control in various applications.

While pneumatic controllers offer numerous benefits, they also present certain challenges that must be considered:

Limited Precision: Compared to electronic controllers, pneumatic systems may offer less precise control, especially in complex processes. This limitation can affect the overall efficiency of operations.

Maintenance: Although pneumatic controllers are low-maintenance, they still require regular inspection and servicing to ensure optimal performance. Issues such as air leaks, clogged filters, or worn components can affect their functionality.

Environmental Impact: The release of compressed air and other gases during operation can contribute to environmental concerns. It is essential to implement proper containment and emission reduction measures to minimize the impact.

Integration with Modern Systems: As the industry moves towards digitalization and automation, integrating pneumatic controllers with modern electronic systems can be challenging. Hybrid solutions that combine pneumatic and electronic control may be required.

As the oil and gas industry continues to evolve, pneumatic controllers will likely remain a vital component of process control systems. However, advancements in technology may lead to the development of more sophisticated pneumatic systems that offer greater precision, efficiency, and integration capabilities.

The ongoing trend towards digitalization and automation may also result in hybrid systems that combine the reliability of pneumatic controllers with the advanced features of electronic controllers. This approach could offer the best of both worlds, ensuring safe, efficient, and cost-effective operations in the oil and gas sector.

Pneumatic controllers are an essential tool in the oil and gas industry, providing reliable and robust control of critical processes. Their ability to function in harsh environments, combined with their safety and simplicity, makes them an ideal choice for various applications. However, as the industry advances, it is crucial to address the challenges associated with pneumatic systems and explore new technologies that can enhance their performance.

By understanding the role and capabilities of pneumatic controllers, oil and gas professionals can make informed decisions about their use in ensuring safe and efficient operations.

By continuing to use the site you agree to our privacy policy Terms and Conditions.