In normal drilling operations, the primary well control is the hydrostatic pressure exerted by the drilling fluid in the well. This pressure can be adjusted to the specific conditions by a variation in the fluid density. Proper well planning requires the hydrostatic head of the drilling fluid to overbalance the formation pressure by a certain safety margin. pressure by a certain safety margin. In case of primary control loss resulting from a sudden increase of formation pressure or lost circulation, it becomes necessary to seat off the well by some other means to prevent an uncontrollable flow, or blowout, of formation fluids. The equipment that performs this secondary control function is the blowout preventer (BOP). BOP's are mounted directly to the wellhead in combinations called the BOP stack. Such a stack will normally contain several of the two basic BOP types: ram and annular. In special situations, a third BOP types the rotating BOP can also be used in combination with rams and annulars.

1) I have made there is a drilling tool in the well.

a semi-closed ram corresponding to the size, of the drilling tool can be used to seal the annular space at the wellhead;

2) There is no drilling tool in the well, the fully sealing ram can fully seal the wellhead;

3) It is necessary to cut the drilling tools in the well, and completely seal the wellhead.

the shearing ram can be used to cut the drilling tools in the well to completely seal the wellhead;

4) The ram of some ram BOPS is allowed to bear weight, and can be used to suspend drilling tools;

5) Have the side holes on the shell of the ram blowout preventer, which can be used for throttling and pressure relief;

6) In conclusion, Ram BOP can be used to seal wells for a long time.

1) Above all, there is a pipe string in the well.

a rubber core can be used to seal, the annular space formed by the pipe string and the wellhead;

2)We let the wellhead can be completely sealed when the well is empty;

3) In the process of drilling and milling, grinding sleeves, logging and salvaging wells.

if overflow or blowout occurs, the space formed by the kelly, cables, wire ropes, tools for handling accidents and the wellhead can be sealed ;

4) With the cooperation of a pressure-reducing, and pressure-regulating valve or small accumulator.

it can forcibly lift, and lower the 18° butt welded pipe string joint without a fine buckle;

5) In case of serious overflow or blowout.

it is used to cooperate with ram BOP and choke manifold to realize soft shut-in.

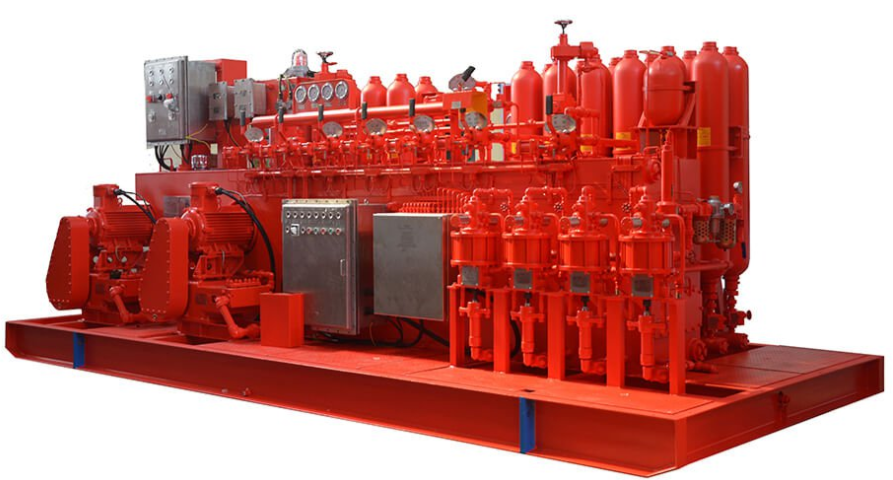

Guangzhou Dongsu Petroleum D&E Equipment Co., Ltd. is one of the earliest professional manufacturers of surface-mounted BOP control system in China. Since the early 1980s, The company is committed to the development, design, research and development of surface-mounted BOP Control Systems, Pneumatic Pressure Test Units, Choke Manifold Control Panel, etc. In 2017, we established a technical service training center integrating after-sales training, maintenance, testing and transformation to provide high-quality and efficient services. For any information about BOP control system, please kindly contact us immediately.

By continuing to use the site you agree to our privacy policy Terms and Conditions.